Buildings, Carbon Footprint, Construction, Embodied Carbon, News, Sustainability

The Impact of Embodied Carbon in Real Estate – Spring Mews Case Study

Embodied carbon is the carbon footprint of producing materials. It is steadily gaining attention from both industry and parts of government, where it is now recognised that embodied carbon emissions make up a large fraction of the emissions from the construction sector. In fact, it’s often 20-40% of the whole life (embodied + operational) carbon emissions of a new building. This is already a significant proportion and will only increase as the thermal standards of new buildings improve.

Unlike operational carbon emissions, embodied carbon cannot be reversed. Once they have been released the opportunity for improvement has passed. In contrast, if a building is constructed with poor operational carbon emissions, whilst it is not ideal they can still be improved, at any point in the lifetime of a building, for example by implementing a range of energy efficiency measures. Embodied carbon reduction is therefore a onetime opportunity. To be taken, or to be lost, forever.

Reducing Embodied Carbon in Construction

Reducing the embodied carbon of buildings can make a valuable contribution to reducing global greenhouse gas emissions. It is often possible to reduce the embodied carbon of a building by around 20% in a cost neutral manner, starting with simple and cost effective reduction measures.

In fact, experience from the infrastructure sector shows that if it is implemented in the correct way embodied carbon assessment can be cost positive. This was explicitly stated in the HM Treasury’s Infrastructure Carbon Review:

“Leading clients and their supply chains have already achieved reductions in capital (embodied) carbon of up to 39 per cent, and 34 per cent in operational carbon. These reductions in carbon have been achieved in association with average reductions in Capex of 22 per cent.”

– HM Treasury, Infrastructure Carbon Review

The challenge was therefore to translate such strong evidence into the building sector.

CLS Holdings, a property investment company which has been listed on the London Stock Exchange since 1994, embarked on an embodied carbon assessment of their Spring Mews development, which is a mixed use scheme in London. The new build development consists of:

- student accommodation (378 x rooms)

- 7 x micro office space

- Hotel (93 x bedrooms)

- Total 16,785 sq m, gross internal floor area

Embodied Carbon Assessment – Carbon Hotspots

The embodied carbon assessment of Spring Mews was undertaken by Circular Ecology. The assessment provided the following carbon hot spots:

- Production of materials = 76% of embodied carbon

- Construction waste = 13%

- Site energy = 10%

- Transport of materials = 1%

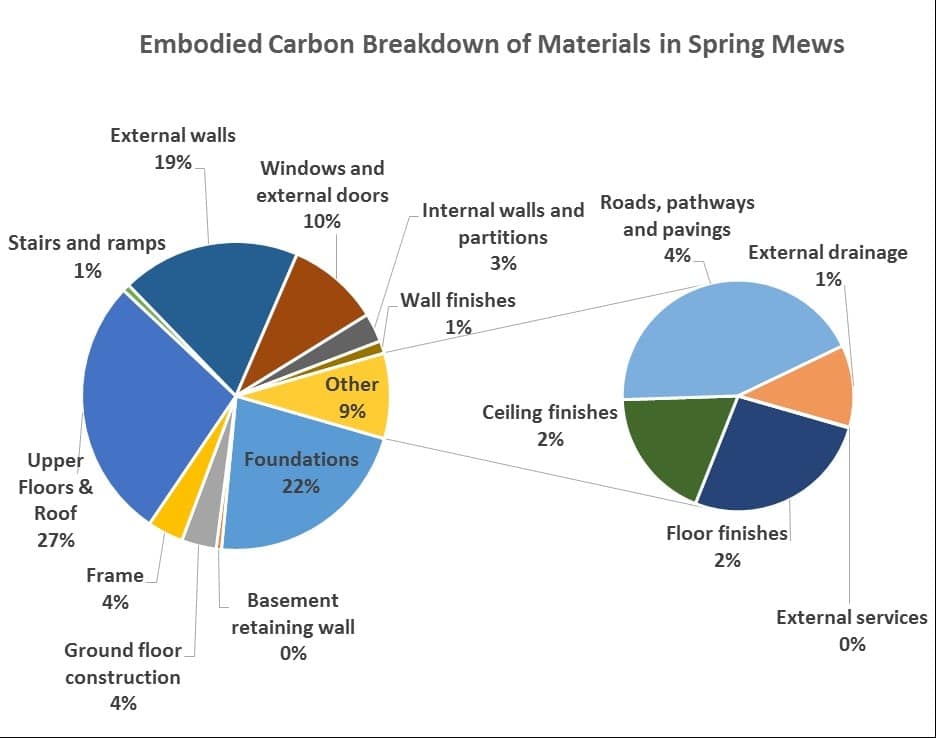

The main carbon hotspot was therefore the embodied carbons of the production of materials, which were broken down further in the below (note the below figure only covers the production of materials breakdown):

The breakdown of materials was therefore diverse. However, categorising these into larger building elements helps to know where the future focus would be best placed.

The main carbon hotspots were:

- Foundations = 17% of the total embodied carbon

- Building envelope = 22%

- Upper floors and roof = 21%

- Construction site = 23% (10% site energy, 13% site waste)

The embodied carbon of site waste arises from the embodied carbon to produce materials that end up as wastage – it is essentially the carbon footprint of making those materials. The embodied carbon of construction waste is often a surprisingly notable contribution to embodied carbon results and is an important hotspot for improvement. As a result, CLS Holdings are currently assessing the embodied carbon profile of the demolition of a building, to determine the main carbon hotspots at the end of building lifetime.

Value of Embodied Carbon Assessment

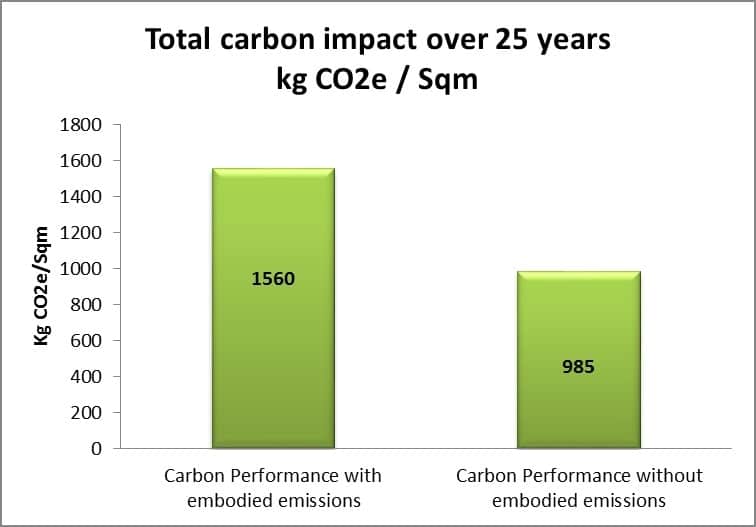

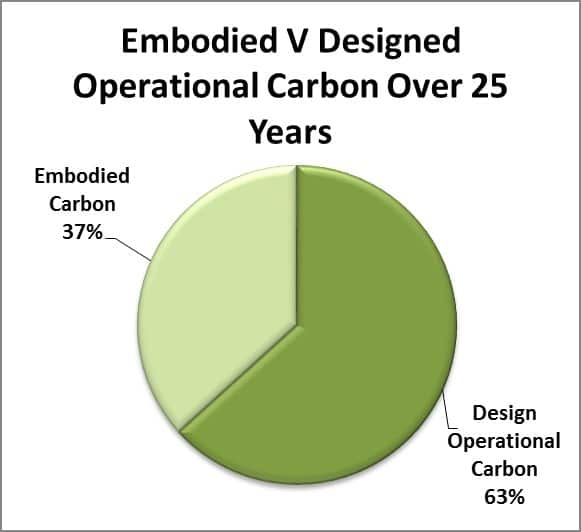

The value of undertaking such an embodied carbon assessment is that it provides CLS Holdings with an understanding of where to focus on future developments. It also provides a better understand on the absolute carbon (operational and embodied) impact over the life of the building, as shown in the figures below.

Shown as a pie chart:

The above comparison uses the designed operational carbon emissions, which doesn’t include operational carbon from activities such as appliances or cooking. However, the embodied carbon of such appliances isn’t included in the calculations (in line with the European standards, EN 15978), so this is a fair comparison.

Bringing Focus and Value to Future Reduction Efforts

Such results provide focus to bring out the value to future reduction efforts.

Rowan Packer, Group Sustainability Manager at CLS Holdings, said “As a result of the project and working with Circular Ecology’s Dr Craig Jones, we now review and consider the building materials of all our projects, whether it be construction, refurbishment, Capex replacement or demolition. Having a better understanding on embodied carbon allows us to have a greater engagement with our supply chain and also opens conversations on scope 3 emission by default. This in my view is a positive step forward.”

This article was originally published on the Better Building Partnership website.

If you like this post please consider sharing it on social media using the share buttons or signing up to our Newsletter.